Inventory accuracy: 5 best practices to improve it

Then, divide it by the inventory value displayed in your inventory management system, and you’ll have the same result. Inventory accuracy is a measure of the difference between your actual inventory and what your records show. Inventory accuracy is crucial to prevent shortages, stock-outs, shrinkage, maintain a positive customer experience, and control inventory quality. And speaking of inventory management systems, have you heard about QodeSETU?

Begin by calculating how many units of a specific SKU you have on hand. Then multiply that figure by 100 and divide it by the recorded stock count for that SKU. You’ll need to perform a physical count of all the available inventory on hand and compare it against what you’re supposed to have. Having inventory inaccuracies is troublesome because it can translate to incorrect customer orders because you have a shortage of product. This can be a loss for your business as a result, or you may even have trouble selling through the inventory you have before it becomes obsolete. Even if you have a good track record with inventory accuracy, there are key things to consider to keep it that way.

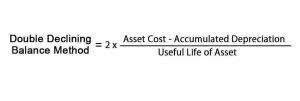

Accurate inventory records empower businesses to make informed decisions about restocking, discounting, and optimizing excess inventory and space. Inventory accuracy is one of the industry’s biggest challenges today. According to Forrester, 56% of retailers say it is a problem for their omnichannel efforts. Many retail brands are having trouble getting it right because most inventory management systems haven’t evolved for modern retail. Some retailers prefer the inventory valuation method to determine how accurate their stock levels are. In this case, you’ll divide your physical stock value by the dollar value recorded in your inventory system.

Track all your Supply Chain KPIs in one place

In most cases, it is the difference between what’s recorded in an inventory management system and what you have available for sale in a store, warehouse, or storage location. Managing inventory plays an essential role in supply chain management, but it isn’t always easy. That’s why retail businesses must consistently track inventory records at the SKU level. A WMS is not just a tool to help users; it is designed to take the focus off of them and let the system do the work. The implementation team takes the time to understand how the system works and implements processes within it to remove human errors, improve onboarding, and make it more intuitive. Then it comes down to continuous improvement within the system to continue improving inventory accuracy.

- A good inventory accuracy rate depends on the industry and business requirements.

- What if customers purchased the remaining 80 necklaces that month, but when the brand went to fulfill those orders, they found out they were five necklaces short.

- Even if you encounter a glitch, you won’t lose everything with backups.

This can quickly get overwhelming, especially if you have a lot of SKUs. Inventory shrinkage will likely throw off your inventory valuation (the monetary value of your unsold stock) when using the retail https://kelleysbookkeeping.com/ inventory method. So, it’s important to correct your electronic records as soon as possible. It might go without saying, but accurate inventory forecasts begin with accurate inventory counts.

Know Everything About Inventory Accuracy: Calculations & Tips

As these tags get scanned, the inventory count gets automatically updated. This technology has significantly reduced our margin of error, and our accuracy has improved. To calculate the accuracy of your inventory, manually count https://bookkeeping-reviews.com/ the number of units currently in stock. Divide that number by the figure in your inventory management system (IMS) and multiply by 100. Sylvia Fountaine had experience being a chef before she started selling products.

Inventory valuation

Pairing barcoding technology with your inventory management system can help you automate warehouse operations. A mobile scanner scans the code found on a product, allowing your inventory management system to track that specific barcode as the product moves through the warehouse. This reduces the time spent searching for items and money spent replacing items that are presumed lost. An average inventory accuracy rate that many businesses maintain is between 60% to 70%. However, it is preferable to have an inventory accuracy rate of above 97% to avoid any unwanted errors and mistakes. In a similar way, if there isn’t a concise process available, the driver could easily drop off the wrong product to the customer.

With effective inventory management, you can facilitate a smoother return process and reduce the number of errors in your inventory records. When calculating your brand’s inventory accuracy rate, keep in mind that the formula only works if you have a reliable stock count. Inventory audits compare your physical stock levels to your current financial records to confirm the correctness of your accounting.

Implement cycle counting

Usually, you compare the recorded inventory number in your inventory management system and what is actually available in your warehouse or store. RFID (radio frequency identification) technology enables you to deploy end-to-end supply chain visibility in your supply chain. Each item’s status is transmitted through an electromagnetic signal to a central database. From there, the WMS automatically analyzes and updates the inventory data in real-time.

Any inaccuracy can cause a heap of troubles throughout your supply chain. Your records could show plenty of stock when you’re down to your last unit. High levels of inventory accuracy are key to running a warehouse and business efficiently. If you can’t see what your products are doing, it will be tough to maintain inventory accuracy. Cogsy has all the functionality to keep your stock levels accurate, from data monitoring to predictive inventory intelligence to enhanced reordering practices. If you’re looking for an operations partner to help improve your inventory accuracy, Cogsy has you covered.

This allows brands to easily monitor inventory, manage products, and generate sales order summaries in mere moments. It takes a well-defined process, training, diligence and the right https://quick-bookkeeping.net/ software. Fortunately, there are steps you can take to improve inventory accuracy. In this article, we highlight what inventory accuracy means, why it matters and how to calculate it.